AQ Assured by AsureQuality, New Zealand's Government-owned food assurance company.

Theland Whole Milk Powder (818g Can)

PRODUCT ATTRIBUTES VERIFIED BY AQ ASSURED

- NZ lower carbon footprint milk supply

- Milk sourced from NZ farms

- Made from 100% raw milk

- Free range cows

Origin

Origin

This product is made in New Zealand

Milk is only sourced from cows in New Zealand.

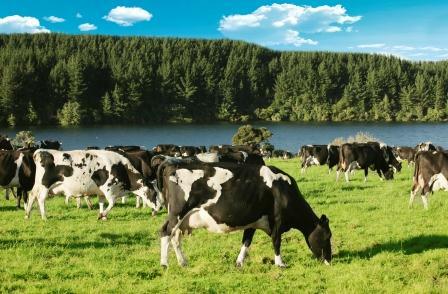

The cows live outside on paddocks throughout the year, roaming freely under New Zealand’s typical 2,000 annual sunshine hours.

Cows graze on fresh pasture as their primary food source. To ensure that their nutritional needs are met, the cows are provided with supplementary feed during winter and poor weather conditions.

Dairy farming practices in New Zealand varies depending on region and season, as climate factors influences grass nutrition and growth.

To ensure efficient use of farmland and continuous supply of pasture, fields are rotated regularly with cow herds being allocated to a specific paddock during each rotation.

In New Zealand, over the entire dairy season there is on average approximately 1 hectare of farmland for every 2-3 cows. With farm rotation, at any given time the cow-to-field density will vary depending on local farming practices, seasonality, weather conditions and cow's natural inclination to form groups as a herd animal.

Milking

The cows are typically milked a maximum of twice a day during the peak dairy season, reducing to once a day in the lower season.

Environmental

Environmental

Theland’s New Zealand milk comes from cows that live outside on paddocks throughout the year.

Outdoor grazing is one factor that New Zealand dairy farmers leverage to achieve the world’s lowest carbon footprint for milk production. This is evidenced by international carbon benchmarking studies.

New Zealand’s dairy farmers are committed to ensuring that the dairy sector remains an efficient producer of low emissions milk by working to further reduce the greenhouse gas emissions produced on farm.

Reduction targets for greenhouse emissions (carbon dioxide, nitrous oxide, and methane) are outlined within the New Zealand’s Government Climate Change Response (Zero Carbon) Act.

The farms where the milk is sourced from are obligated to comply with the environmental regulations prescribed by New Zealand's Regional Councils.

Theland Farm Whole Milk Powder is produced in compliance with New Zealand's Resource Management Act (2009), and local council Resource Management Plans, which set out rules and regulations around management of the New Zealand environment.

These rules include:

• Disposing of waste in ways that prevent pollution

• Controlling manufacturing emissions to ensure air quality is maintained

• Using only approved chemicals in a way that will not harm the environment

• Operating within a safe distance of waterways to avoid erosion and protect water quality

• Nutrient management

Social & Ethical

Social & Ethical

Animal Welfare

All milk suppliers for Theland products are obligated to meet the New Zealand Animal Welfare Standards.

The standards require animals to be allowed the following five freedoms;- Freedom to display normal patterns of behaviour

- Freedom from thermal and physical discomfort

- Freedom from thirst, hunger and malnutrition

- Freedom from distress

- Freedom from, or rapid treatment of, illness or injury

Halal

This product has been produced in accordance with Halal principles. Whole milk powder sourced is Halal certified.

Safety & Quality

Safety & Quality

Laboratory Tested for Safety

Theland Milk Powder products are laboratory tested for safety throughout the production process at independent and accredited laboratories. Testing is undertaken at each step from raw milk collection, during processing, and again upon completion of the final product.This testing regime also ensures all final products meet the nutritional descriptions on their label. Samples are tested for harmful bacteria or other contaminants.

Produced Under New Zealand Government Regulations

New Zealand has Acts and Regulations to ensure all dairy products produced are safe for consumers and that manufacturers use fair and sustainable practices. All dairy products must comply with the Animal Products Act, 1999 and all milk suppliers must meet the New Zealand Animal Welfare standards. These regulations include:

- No hormones or growth promotants are permitted

- All food safety hazards must be controlled using Codex based Hazard Analysis Critical Control Point (HACCP) principles

- All chemicals used on a manufacturing site must be approved by the New Zealand Government’s Ministry for Primary Industries

- Hygiene standards for facilities, equipment and people must be met

- All producers, manufacturers, transporters, packing and storage facilities operate a Risk Management Programme

Meets Overseas Market Access Requirements (OMAR)

Auditing

The contract processor's factory environment, processes and records are routinely audited in order to uphold their Risk Management Programme (RMP), Hazard Analysis & Critical Control Points (HACCP), Good Manufacturing Practises (GMP), Halal and other certifications. There are also unannounced regulatory audits conducted randomly to ensure compliance.

Nutrition

Nutrition

The 100% raw milk sourced from New Zealand is standardised according to CODEX regulations.

Theland Farm Milk Powder contains no added colouring agents, sweeteners, thickening agents, gelatin, or preservatives.

This product contains 100% natural protein. Protein is important for the growth and repair of the body’s cells and for building muscle.

This product contains 100% natural milk calcium and additional Vitamin A and D.

Calcium plays an essential role in the development of healthy bones and teeth. Vitamin D enhances absorption of calcium for strong healthy bones.

Vitamin A is an anti-oxidant that helps maintain integrity of skin and mucus membranes. It is essential for healthy eye-sight and helps prevent macular degeneration of the retina in the elderly population.